MV Pre-Molded Cable Accessories

In 1987, we purchased a complete set of technology, equipment, molds, and special silicone rubber raw materials for silicone rubber pre-molded power cable accessories through an agreement with Siemens in Germany. Including indoor/outdoor termination, cable joint of 10kV, 20kV and 35kV. In January of 1990, we designed and manufactured the first national silicone rubber power cable termination and joint. Since then, series of silicone rubber power cable termination and joint of 35kV and below have been put into mass production and ran on the grid.

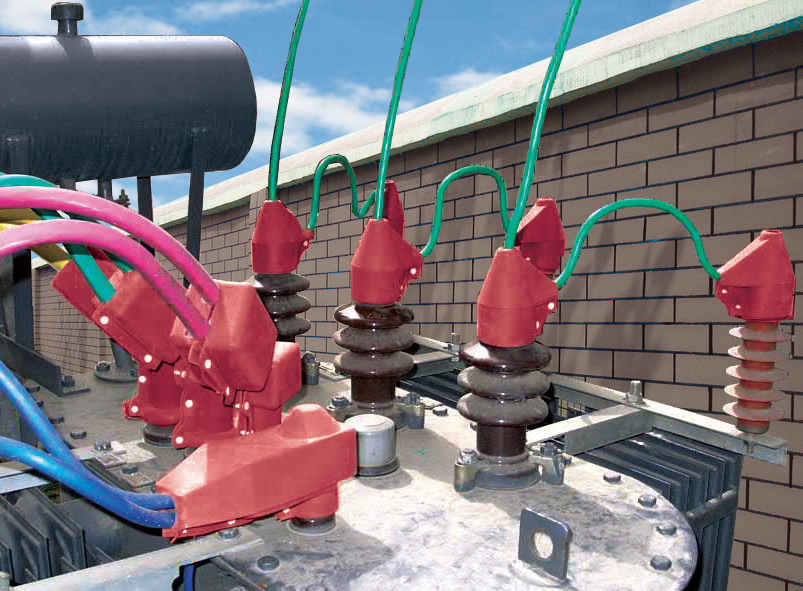

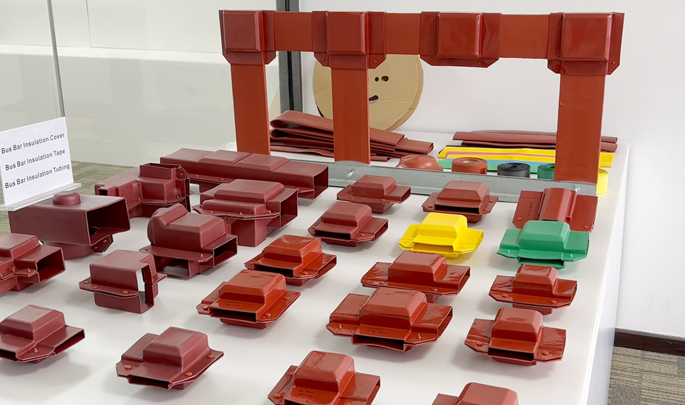

| In 1990, 15kV pre-molded outdoor termination installed in Guangzhou. It was the most reliable and state-of-the-art cable accessories at the time. | In 1996, 24kV pre-molded outdoor termination installed in Tehran Metro Project. The silicone rubber has excellent performance of ultra violet resistance, anti-ageing, weather resistance, anti-corrosion anti- tracking, and good hydrophobicity. The hydrophobicity performance can transfer to the dust surface. All these properties and reliable production as well as technical support keep the products good condition for 27 years after installation. | |

|  | |

In 1996, 24kV pre-molded indoor termination installed in Tehran Metro Project. | In 2003, 35kV pre-molded straight through cable joint installed in Shanghai Pearl Light Rail Transit project. | |

|  | |

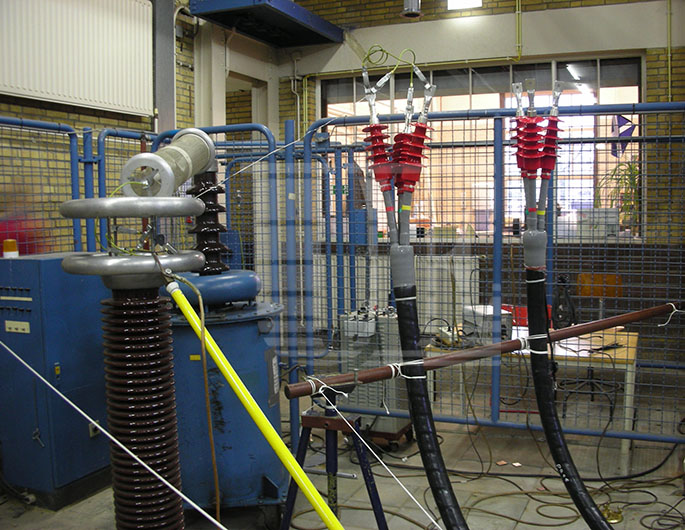

In 2008, 15kV pre-molded outdoor termination passed Type Test According to IEC 60502 Standard in KEMA Netherland laboratory. | ||

|  | |

In recent years, our pre-molded cable termination and joint are increasingly applied in wind power generation. For decades we have received compliment from users for its stable reliability. | ||||

|

|  | ||